24/7 Lift Maintenance Repair: Prompt and Efficient Solution

24/7 Lift Maintenance Repair: Prompt and Efficient Solution

Blog Article

Unlocking the Secrets to Efficient Lift Repairs: Expert Insights Revealed

In the realm of lift repair and maintenance, uncovering the methods that lead to effective and reliable solution is similar to figuring out a complex challenge. As we begin on this journey to debunk the keys behind streamlined lift repair work, a globe of possibilities arises, guaranteeing a future where downtime is decreased, safety is focused on, and operational excellence comes to be the norm.

Usual Lift Repair Work Obstacles

One more common challenge in lift repair work is the lack of proper upkeep documents. Without exact maintenance records, repair technicians may battle to detect concerns successfully or expect prospective issues. This can result in longer repair times and raised prices as service technicians work to troubleshoot concerns without historical data to direct them.

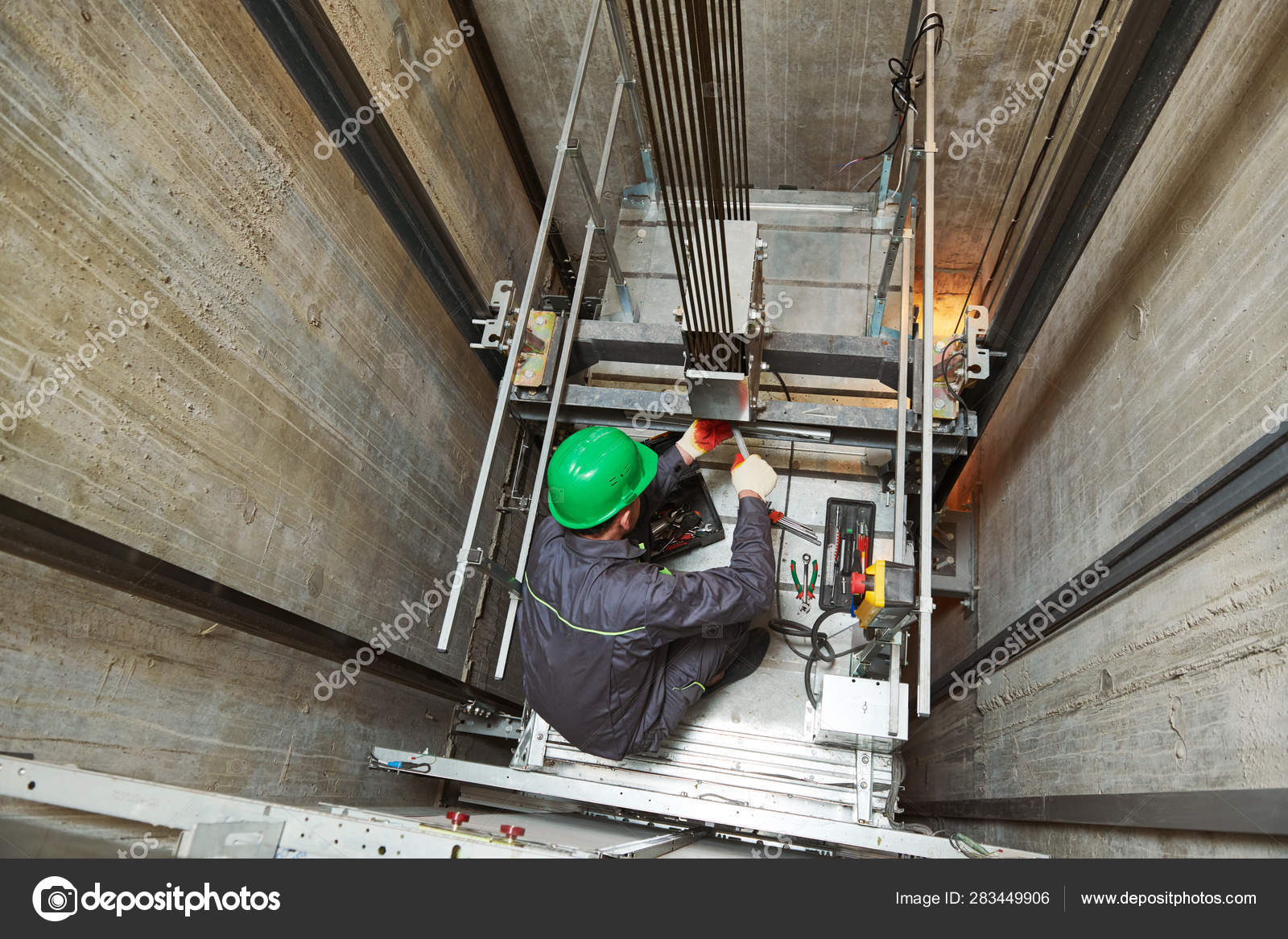

Moreover, accessibility issues within lift shafts can posture substantial obstacles during repairs. Minimal area, awkward angles, and intricate equipment can make it challenging for service technicians to reach the necessary parts for repair, extending the overall fixing procedure - Lift Maintenance Repair. By attending to these typical obstacles proactively, lift repair work specialists can improve operational effectiveness and ensure the smooth functioning of upright transportation systems

Proactive Upkeep Techniques

Applying positive upkeep techniques is extremely important for guaranteeing the longevity and ideal efficiency of lift systems. By adopting a positive approach to maintenance, structure supervisors and lift upkeep teams can resolve potential problems prior to they escalate right into pricey repairs or downtime. One efficient strategy is to develop a normal maintenance routine that includes comprehensive examinations, lubrication of relocating components, and testing of security attributes.

Additionally, purchasing training programs for upkeep team can boost their abilities in recognizing possible concerns and performing preventive maintenance tasks efficiently - Lift Maintenance Repair. By equipping maintenance teams with the knowledge and tools needed to proactively maintain lift systems, structure proprietors can minimize disruptions, extend the life-span of their lifts, and make certain a safe and reliable vertical transportation experience for passengers

Fixing Methods

Efficient fixing techniques are crucial for quickly recognizing and fixing issues with lift systems to decrease downtime and guarantee optimum performance. One reliable technique is to begin with a comprehensive aesthetic inspection of the lift elements, inspecting for any visible indicators of misalignment, wear, or damage.

Enhancing Fixing Abilities

Enhancing efficiency in lift system fixings is an essential facet of guaranteeing optimum capability and lessening functional interruptions. Lift technicians need to continually work on sharpening their repair skills to fulfill the demands of contemporary lift systems.

In addition, staying updated with the most recent developments in lift modern technology is essential for service technicians aiming to enhance their repair work abilities. This entails proactively seeking info regarding brand-new parts, software updates, and maintenance techniques to efficiently identify and fix concerns. By investing time and effort into constant discovering and functional experience, lift professionals can dramatically increase their repair work proficiencies and add to the effective functioning of lift systems.

Raising Maintenance Criteria

Elevating maintenance standards in lift systems is critical for making sure extended operational efficiency and safety. Regular maintenance not just boosts the efficiency of lift systems however also reduces the risk of unexpected breakdowns and makes certain the safety and security of customers. By sticking to stringent upkeep procedures, lift proprietors and operators can dramatically lower the probability of expensive repair work and downtime.

Implementing a comprehensive upkeep routine that includes normal evaluations, lubrication of moving parts, and positive substitute of used parts is critical. Making use of sophisticated technologies like IoT sensing units and predictive upkeep software application can help in keeping track www.lift-maintenance-repair.co.uk/ of the lift's problem in real-time, allowing prompt treatments before problems escalate. Furthermore, offering continual training for maintenance staff on the most up to date industry criteria and best techniques is vital for upholding maintenance quality.

Moreover, fostering a culture of liability and attention to detail amongst upkeep teams can better elevate upkeep criteria. Encouraging open communication networks for reporting and resolving maintenance problems promptly can assist in keeping a high degree of lift system reliability. Ultimately, by prioritizing and raising upkeep standards, lift systems can operate effectively and safely for a prolonged duration.

Verdict

In verdict, efficient lift repair work require positive maintenance methods, fixing methods, and boosted repair service abilities. By dealing with typical difficulties and raising maintenance standards, maintenance professionals can efficiently guarantee the smooth operation of lifts - Lift Maintenance Repair. Executing these expert insights can lead to boosted performance, minimized downtime, and enhanced safety for both passengers and tools

In the world of lift repair service and maintenance, uncovering the methodologies that lead to efficient and reliable service is comparable to decoding a complicated challenge.An additional prevalent challenge in lift fixings is the absence of proper upkeep documents. By adopting an aggressive technique to maintenance, building managers and lift upkeep teams can deal with prospective concerns prior to they escalate right into costly repairs or downtime.In final thought, effective lift repair services require aggressive upkeep approaches, repairing techniques, and boosted fixing abilities. By dealing with common difficulties and elevating upkeep standards, maintenance specialists can efficiently make certain the smooth operation of lifts.

Report this page